Stainless Steel Fabrication

1

Material & Fabrication Standards

Material: AISI 304 Stainless Steel (food-grade), thickness 1.2–1.5 mm for tops, 1.0–1.2 mm for undershelves and panels.

Finish: No.4 (satin) finish.

Welds: Argon TIG welded, smooth ground, and polished.

Edges: Double-folded and reinforced for durability.

Supports: Heavy-duty stainless steel box sections or adjustable bullet feet.

2

Work Table

Preparation tables (with or without undershelf), Wall tables (single or double overshelf), Butcher block / cutting tables, Dish sorting / landing tables, Pastry / bakery work tables. Material: AISI 304 Stainless Steel (food-grade), thickness 1.2–1.5 mm for tops, 1.0–1.2 mm for undershelves and panels. Finish: No.4 (satin) finish. Welds: Argon TIG welded, smooth ground, and polished. Edges: Double-folded and reinforced for durability. Supports: Heavy-duty stainless steel box sections or adjustable bullet feet.

3

Sink & Wash Units

Single / double / triple compartment sinks, Pot wash sink units (deep bowl type), Hand wash sinks with knee or sensor operation, Vegetable / meat / fish wash sinks, Mop sink / janitor sink units. Material: AISI 304 Stainless Steel (food-grade), Finish: No.4 satin, Welds: Argon TIG welded, smooth polished.

4

Cooking Line Fabrication

Custom base stands for cooking equipment, Equipment support frames (for ovens, ranges, etc.), Splash guards and divider panels, Control panels and undershelves, Exhaust plenum / hood skirt fabrications. Material: AISI 304 Stainless Steel, Finish: No.4 satin, Welds: Argon TIG welded, smooth polished.

5

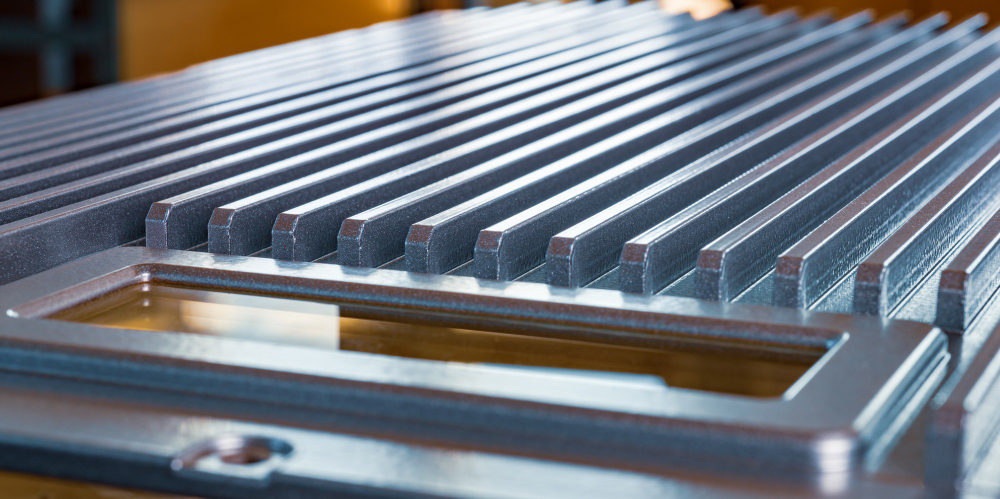

Floor Grattings

Custom made floor grattings for commercial kitchens and industrial areas. Material: Heavy-duty stainless steel, TIG welded and polished for hygiene and durability.

6

Cabinets & Enclosures

Under-counter cabinets (hinged or sliding doors), Wall cabinets with adjustable shelves, Electrical / gas control cabinets, Waste collection cabinets (with bins), Chemical / cleaning material cabinets. Material: AISI 304 Stainless Steel, Finish: No.4 satin, Welds: Argon TIG welded, edges double-folded for strength.